Well Plate Assembly

- Client: Dr. John Finan, Northshore Research Institute

- Role in Project: Design research, qualitative user research, machining, user testing synthesis

- Skills: Prototyping, machining, milling, laser cutting, research, user-centered design

Design Challenge: A multi-step process creates a 96 well plate assembly with a unique silicone-lined bottom but currently, the silicone sheet does not adhere to the well plate with a consistent flatness and the dimples introduce error into the imaging of the cells.

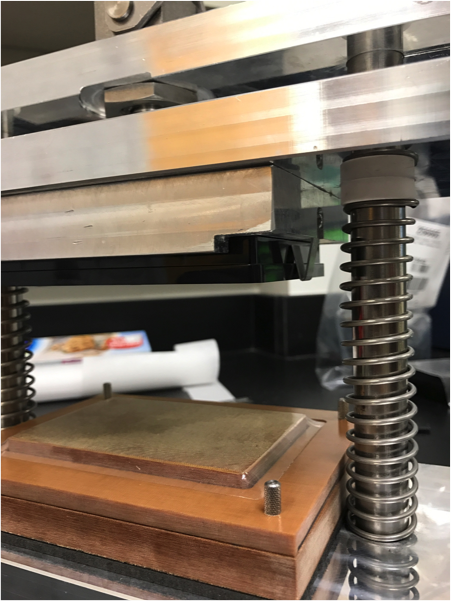

Design Solution: The 3-Step Tension Frame reduces handling errors of the activated silicone, introduces consistency, and pre-tensions the silicone to reduce dimpling.

Key Features: The design is made of a phenolic composite material. A press-fit frame grips the silicone, an island block introduces tension to the silicone and four thumb screws hold the frame together.

Design Overview: 3-Step Tension Frame

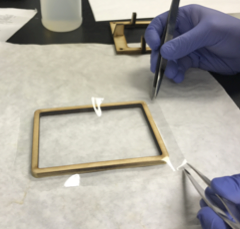

Design Feature: Grip

Design Feature: Contact

Design Feature: Tension

Problems Encountered: Spring Clip Interference & Snap Frame

Next Steps: Quantitatively Measuring Success

The Team: Andrew McIntosh, Simon Zhao, Wendy Roldan